Add :Sha he building materials base, nanqiao district, Chuzhou, Anhui province

Tel :+86 550 3971188

Fax: +86 550 3962288

Email:hcx_ibm@huachengxing.com

phone: +86 19805508855

Zip code: 239060

Location:Home>News>Industry information

Add :Sha he building materials base, nanqiao district, Chuzhou, Anhui province

Tel :+86 550 3971188

Fax: +86 550 3962288

Email:hcx_ibm@huachengxing.com

phone: +86 19805508855

Zip code: 239060

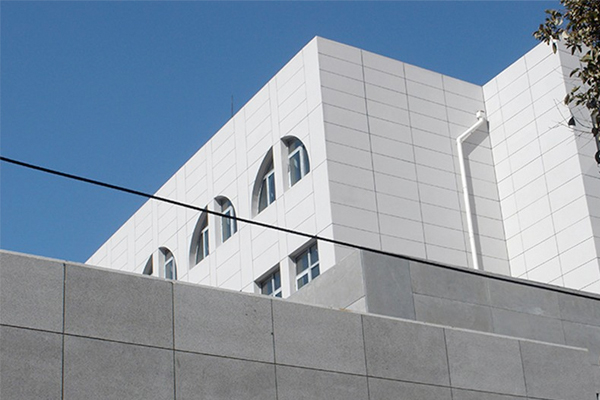

Solid Color Through Panels are manufactured using high-quality, fire-resistant raw materials, including selected quartz powder, mineral powder, fireproof plant fibers, and a variety of mineral fibers. These are supplemented with cement and specialized fire-retardant materials and processed through advanced production techniques such as molding, pressurization, and steam curing. The resulting panels achieve the national building materials Class A1 non-combustible rating, offering a fire resistance period of up to 5 hours, excellent resistance to high-temperature cracking, zero methanol content, and strong resistance to fire and microbial corrosion.

Key Feature:

Standard Specifications

Thickness: 6mm, 8mm, 10mm, 12mm

Standard sizes: 2400×1200mm and 2440×1220mm

Applications

High-end residential buildings

Medical and hygiene facilities, such as cleanrooms and operating rooms, for ceilings and wall lining panels

Swimming pools, gymnasiums, and other environments requiring moisture-resistant ceiling panels

With their uniform color and rich visual expressiveness, designers can utilize varied color combinations and staggered installation patterns to showcase unlimited creative architectural potential.

The panel’s color is consistent throughout its entire thickness—surface and core are of the same hue—ensuring a seamless appearance even on cut edges, which is especially valued in visible architectural details.

Anhui huachengxing building materials technology co., LTD. ©️ disclaimer ICP17001972号

design by:www.ibw.cn